Hardworking

Lasers

About US

B-Lasers is US based laser platform offering business development in North America for laser systems and laser micromachining systems.

With more than 25 years in the laser industry, we strive to help our partners expand their business and reach North American markets with a mindset of collaboration, hard work, and commitment to their most advanced technologies.

Robert Braunschweig received his MS in 1997 from the School for Advanced Processes in Electronics and Optics (ESPEO) in Orleans, France, with a major in Lasers and Photonics.

He has spent the last 27 years in the laser industry with positions ranging from R&D, Product Development, Head of Manufacturing, Technical support and Sales and Business Development.

Robert was the US Sales Manager for Amplitude Lasers, a leader in Ultrafast diode pumped lasers, where he helped develop the North American business from 2007–2014.

Most recently, he started LASEA US Operation and helped grow their business in North America until 2022.

Throughout his career, Robert has been involved in every aspect of the laser industry, from R&D to sales and business development. He is familiar with industrial markets such as Medical Devices, Semiconductors, Display, Life-Science, Medical…

He is knowledgeable in all solid state laser technologies and solutions. Robert approaches his duties with a “hardworking” ethic and strives to bring the best technology made available by his partners to the North American market.

B-Lasers was created to be the ultimate laser platform, Hardworking Laser Platform.

Partners

Multibeam Technology

QiOVA develops and markets the world’s fastest laser marking and micromachining solutions, thanks to its patented multibeam technology.

QiOVA, founded in 2011 and headquartered in Andrézieux-Bouthéon, France, is a pioneering company in laser processing solutions, specializing in high-speed laser marking and micromachining. Their flagship innovation, the VULQ1 platform, utilizes patented programmable multibeam technology to generate hundreds of laser beamlets from a single source, enabling ultra-fast, high-precision marking. This technology allows for the marking of 2D codes in a single laser pulse, significantly enhancing throughput and efficiency in industrial applications. QiOVA’s solutions are particularly suited for industries requiring rapid, precise, and environmentally friendly marking processes, such as pharmaceuticals, electronics, and luxury goods. By integrating their advanced laser systems into production lines, manufacturers can achieve high-speed, contactless, and permanent marking without the need for consumables, aligning with sustainable manufacturing practices.

High Power, agile, visible and UV fiber lasers for high throughput, high precision micromachining applications

YUCCA is an industrial grade laser designed for high precision manufacturing processes in 24/7 production environments.

Yucca comes in up to 100W UV and 120W Green variants.

PROGRAMMABLE PULSES

CAREX, the flexible nanosecond UV fiber laser, delivers fully programmable pulses combining high power and high pulse repetition rates. It is especially designed for high precision micro-processing.

Carex comes in up to 45W UV and 80W Green variants.

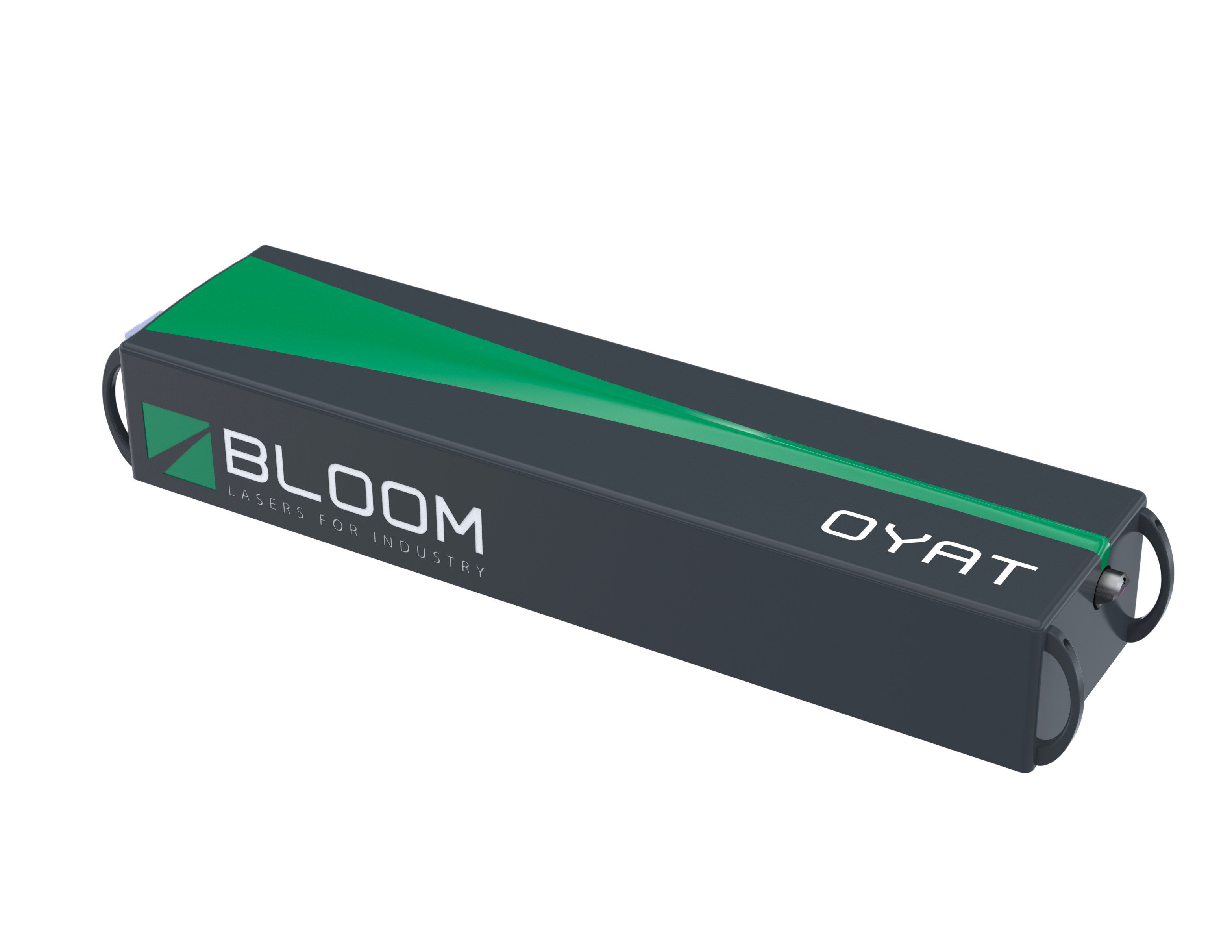

OYAT, the quasi-continuous fiber laser, delivers high power and high frequency picosecond pulses.

Oyat comes in up to 50W UV and 80W Green variants.

BLOOM puts customer care and satisfaction in the core of its daily operations and strategic decisions. Since its creation, BLOOM has built an operational service team with local service installations for fast response time to our customers.

BLOOM designs, manufactures and delivers stable, reliable and long-term operations lasers for 24/7 environment productions. Its lasers are built on a fiber technology both mature and field proven. BLOOM has implemented high-end methodologies supporting design, quality and serviceability for 24/7 industrial operations.

BLOOM is installed in a brand new production facility including an ISO6 clean room, and is capable of high volume manufacturing and fast production ramp-up. With minimum assembly and alignment steps thanks to the fibered design, leads times are shortened.

Choosing BLOOM lasers for your microprocessing application is investing on the future with a scalable technology that will sustain faster throughput and cost reduction of your machines.

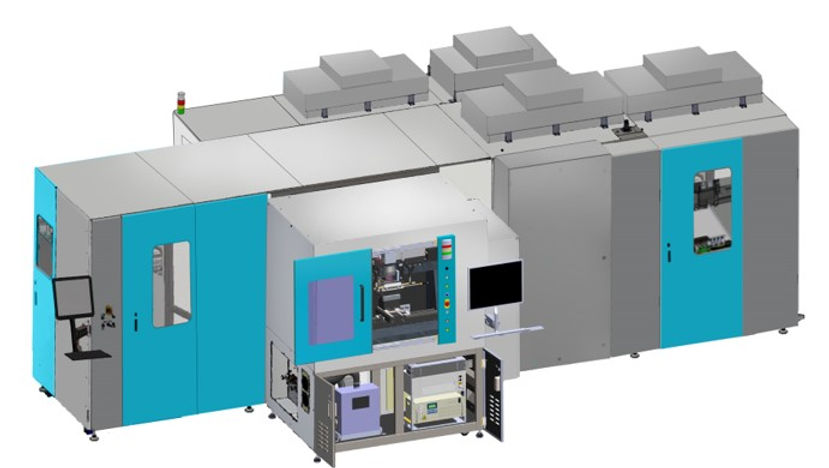

TLS offers platforms that are designed to be compatible with a variety of automation options, such as wafer-based robotic systems , roll-to-roll (R2R) handling, conveyor systems, 6-axis robots and a variety of other customer automation modules.

Turner Laser Systems (TLS) specializes in custom-built laser systems for industries like medical devices, electronics, aerospace, and energy. They provide easy-to-use, precision laser equipment designed for specific manufacturing needs, from small prototypes to large-scale production. TLS guides clients through the entire process—from initial design to ongoing support—to ensure effective and reliable solutions.

News and Events

Coming soon